Automatic Vial Dryer

Dry vials in as little as 5 minutes

Temperature-sensitive products, such as vaccines, serums, and tests, typically spend 24-48 hours out of the cold chain during the packaging process. This temperature excursion can reduce the potency and efficacy of critical medicines.

With Garvey’s automatic vial dryer, you can reduce time out of the cold chain to as little as 5 minutes. This innovative solution combines our patented pressureless loop technology with a high-volume laminar flow accumulator to dry vials and single-file them to a labeler or inspection machine at rates up to 900 vials per minute — the fastest out-feed rate in the industry.

Our automatic vial dryer is highly flexible thanks to its modular design, and it can be configured to fit in even the tightest production line layouts. The machine can handle products ranging from 2ml lyophilized vials to 50ml liquid-filled vials. Various in-feed and out-feed options are available.

Increase Efficiency

Maintain Cold Chain Integrity

Boost Productivity

Eliminate Backpressure

Reduce Vial Damage

Multi-Functional

Dry Vials Quickly

Accumulate and Single-File

Feed Inspectors, Labelers, and Other Packaging Equipment

Lean Manufacturing

Minimize Energy Use

Reduce Operator Interventions

Minimize Friction & Noise

Simple Design

Gentle Handling

Low Maintenance Costs

Best Return on Investment

Proven Industry Results

Lowest Operation Costs

Request a quote

Please provide the details about your project below. Our team will review the information and reach out to you as soon as possible.

Upper Enclosure

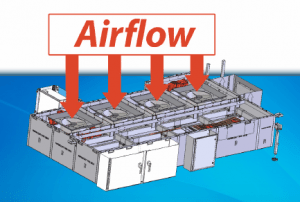

The optional enclosure is fabricated using a stainless steel frame structure with 3/8” thick polycarbonate door panels. The panels open easily to allow access to vials and when closed, they help reduce noise levels to below 75dB. The enclosure encourages consistent laminar flow and when combined with the lower air duct, it also enables a Hepa filtration system to be installed above the table to create a closed-loop drying system.

Lower Air Duct

Instead of the fan exhausting from louvered side panels, you can choose to guide the air to either end of the vial dryer through an air duct installed beneath the fans. The exhaust can then be directed to any location using standard HVAC system components.

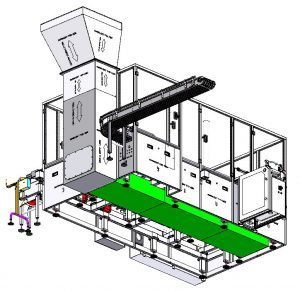

Manual Tray Loader

Garvey’s manual tray loader can be configured to feed various tray and vial sizes onto the dryer section. The innovative design captures the edge of the tray by raising slightly as it is positioned for loading.

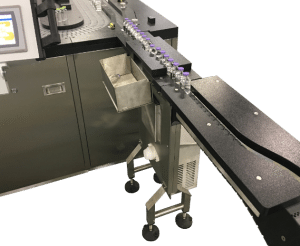

Down Vial Reject Device

As the dried vial exit the machine in a single row, this device will reject any vials that are lying down. The vials are gently guided into a stainless steel bin which is lined with a soft rubber cushion.

HMI Strong Arm Mount

Our precision-designed products combine the ruggedness of our industrial displays with our wide range of fully customized enclosures, articulating arms, unlimited mounting solutions, and wide range of accessories including keyboards, pointers, PCs and Thin Clients to provide the ideal solution for any operator interface application.

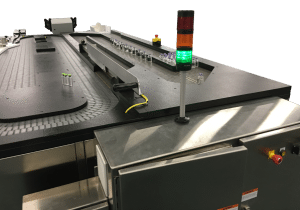

Andon lights

Andon lights come in handy because of their relative simplicity and their ability to be seen from a distance and attract the eye, especially in places where noise is high and other signals might not be noticed. Depending on the color that displays, workers can immediately rectify problems and get the production line moving again.