Every product has its own unique packaging challenges. When it comes to rectangular objects, getting them from a mass flow into a single file with a narrow edge ledge quickly and efficiently can be difficult. In many cases, multiple pieces of equipment are used to move products from one of these processes to the next. This is not only expensive, but it takes up a lot of space.

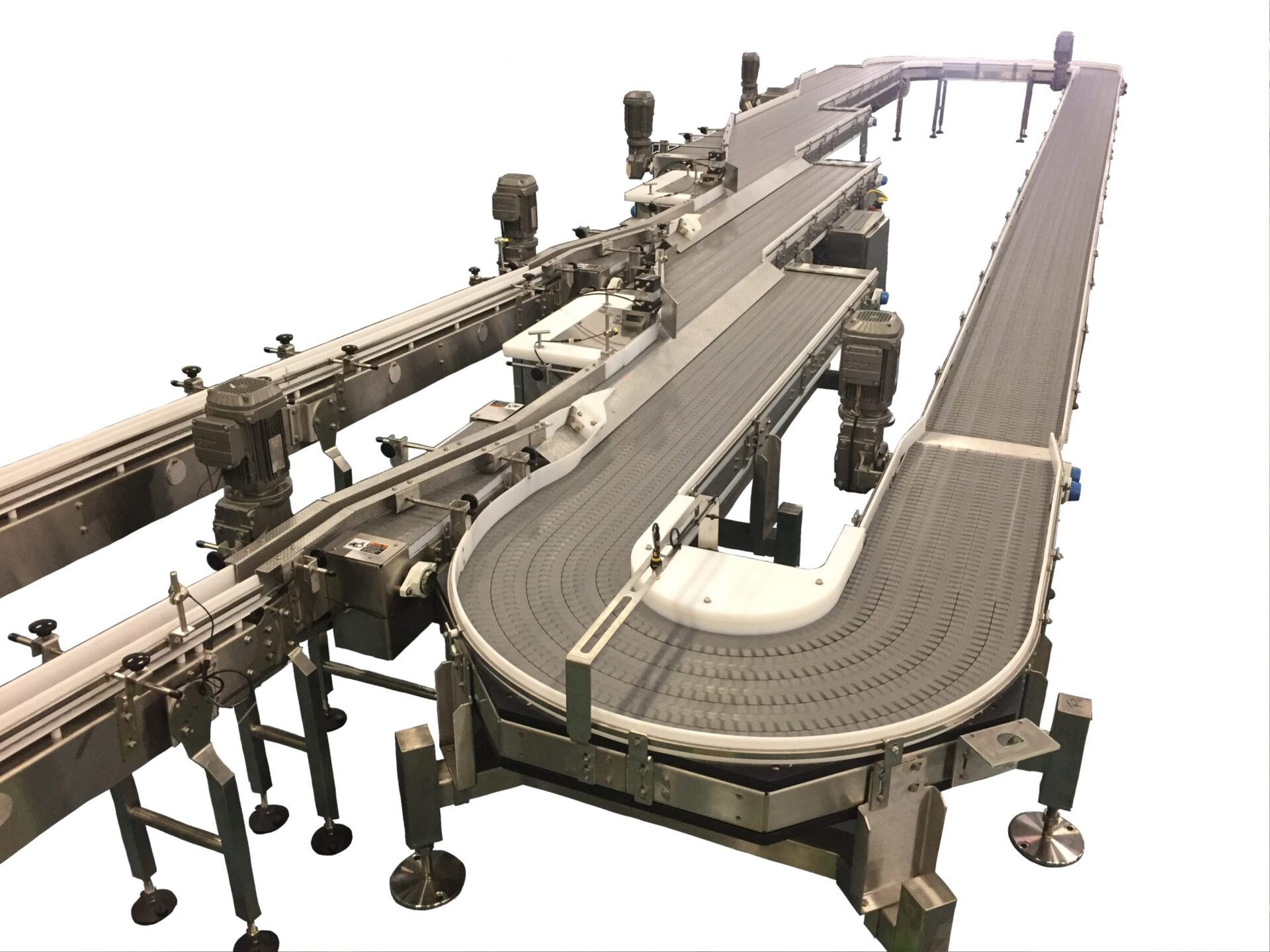

The 3D Infinity Accumulator was designed with this specific processing challenge in mind. This machine helps manufacturers simultaneously orient and single-file products into multiple lanes at high speeds.

Benefits of Using One Multifaceted Piece of Equipment

The 3D Infinity is an accumulator that is capable of much more. It provides all the benefits of an accumulator, including minimizing line downtime by keeping your constraint running and maximizing your throughput. However, the 3D Infinity also simultaneously orients and single-files products.

This enables manufacturers to rely on a single piece of equipment rather than having to use multi accumulators, conveyors, and processors. In fact, the 3D Infinity can act as a combiner (infeeding multiple lanes, a single-filer (outfeeding into a single), laner (outfeeding to multiple lanes), or as an unscrambler. These benefits combined give the 3D Infinity the best ROI available for this type of equipment.

The Advantages of Using the 3D Infinity

- Reduces the machine footprint

- Lowers spare parts and maintenance costs

- Decreases energy consummation

- Combines accumulation, orientation, and single-filing

Industry Applications

The 3D Infinity was originally designed for the food industry, and it’s used widely for both direct food contact and non-food contact applications but can be used across an array of industries for processing and packaging.

Product Processing Examples with the 3D infinity

- Frozen food trays

- Packaged and unpackaged granola bars, snack cakes

- Frozen meat and plant-based patties

- Tubes of glue

- Eye drops

Designed to Meet the Highest Safety Standards

Garvey Corporation’s accumulators are meticulously designed to meet and exceed the strictest safety standards. It’s a top priority to ensure that our machines are easy to clean, both inside and out, allowing for efficient sanitation processes and minimal downtime.

Our innovative design features angled interior surfaces, which prevent debris and contaminants from accumulating in hard-to-reach areas. This not only ensures a hygienic production environment but also reduces the time and effort required for cleaning. Additionally, we have minimized metal-to-metal contact in our accumulators, reducing the risk of wear and tear, as well as potential contamination caused by metal shavings or particles.

This design choice enhances the durability of our machines, extends their service life, and contributes to maintaining a safe and clean production environment. Ultimately, the 3D Infinity is easy to clean inside and out, all interior surfaces are angled, and metal-to-metal surfaces are minimal.

Optimize Your Line and Maximize Your Production

Every product has different properties. If you have a unique item, you can always schedule a test with our team. Our experts can help you discover how an accumulator like the 3D Infinity handles your products and calculate how it improves your throughput. If you have any questions or want to schedule a test, contact us!